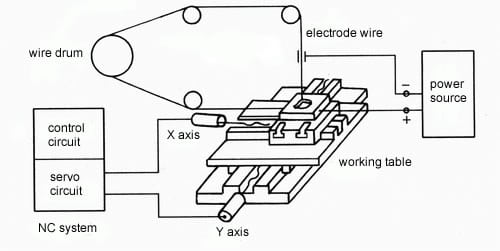

wire edm machine working principle

Typically the electrode diameters range from 004 012 10mm 30mm although smaller and larger diameters are available. It works on the thermo-electrical phenomenon.

Deep Hole Drilling Machines Gundrill Vastuna Ltd

Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece.

. It was first introduced in 1770 by Joseph Priestly. How does wire EDM work. Small Fast Hole EDM and wire-cut EDM.

Electrical discharge machining EDM is a material removal or manufacturing technique. Principle Working Advantages and Disadvantages. As the electric discharge takes place between an electrodewire and workpiece the thermal energy is generated on a workpiece.

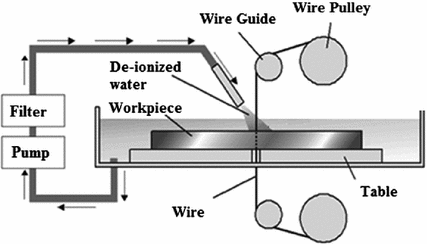

The working principle of wire EDM machining is a process of separating metal materials by melting after the heat generated by electric spark discharge reaches the melting point of metal materials. Explanation about eletrical discharge machining wire cut working principle wire EDM animation and wire EDM application by machining a mouldOther interestin. WEDM process is based on the conventional EDM sparking phenomenon utilizing the widely accepted non-contact technique.

Ad Maintain Your EDMs Performance With High Quality Wire Consumables. However with the modernization of technology and equipment this technology is now. Usually they are non-ferrous and include steel titanium.

Wire edm machine working principle Friday March 11 2022 Edit Sometimes it is necessary to make a double jump if the distance between objects is large and one jump is not enough to overcome it. EDM Electro Discharge Machining Wire Erosion is a precision engineering process where a work piece is cut through with a strand of wire it creates electrical sparks between the wire and the work piece and these electrical sparks cut the work piece. Wire electrical discharge machining WEDM is an advanced thermal machining process capable of accurately machining parts with complicated shapes especially for the parts that are very difficult to be machined by traditional machining processes.

Cnc wire edm is a special purpose machine used for the tool and die makingthis video is only for the education purpose to spread the knowledge about machines. This leads to the removal of a material layer. Generally there are three types of EDM machines.

A non-conventional process though hardly a new one wire EDM works on parts resistant to conventional machining processes but only if these parts are electrically conductive. Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the. Wire electrical discharge machining WEDM uses a metallic wire to cut or shape a workpiece often a conductive material with a thin electrode wire that follows a precisely programmed path.

It was invented by the former Soviet Union in the last century but China applied this technology to industrial production for the first time. Posted on September 6 2021 by sansmachining. Electrical Discharge Machining EDM.

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Welcome Cnc Machine Design Desktop Cnc Cnc

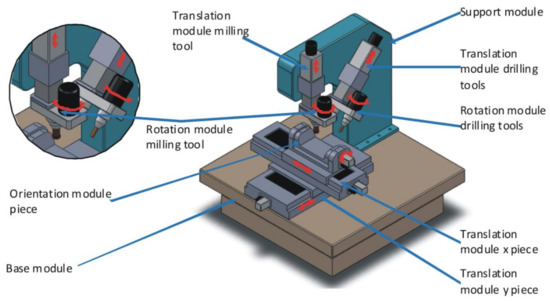

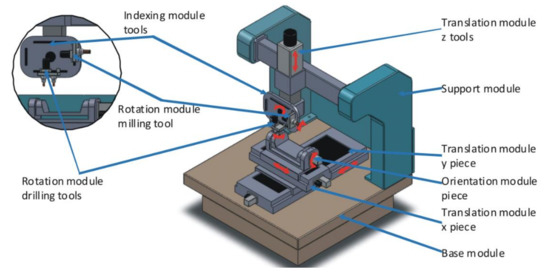

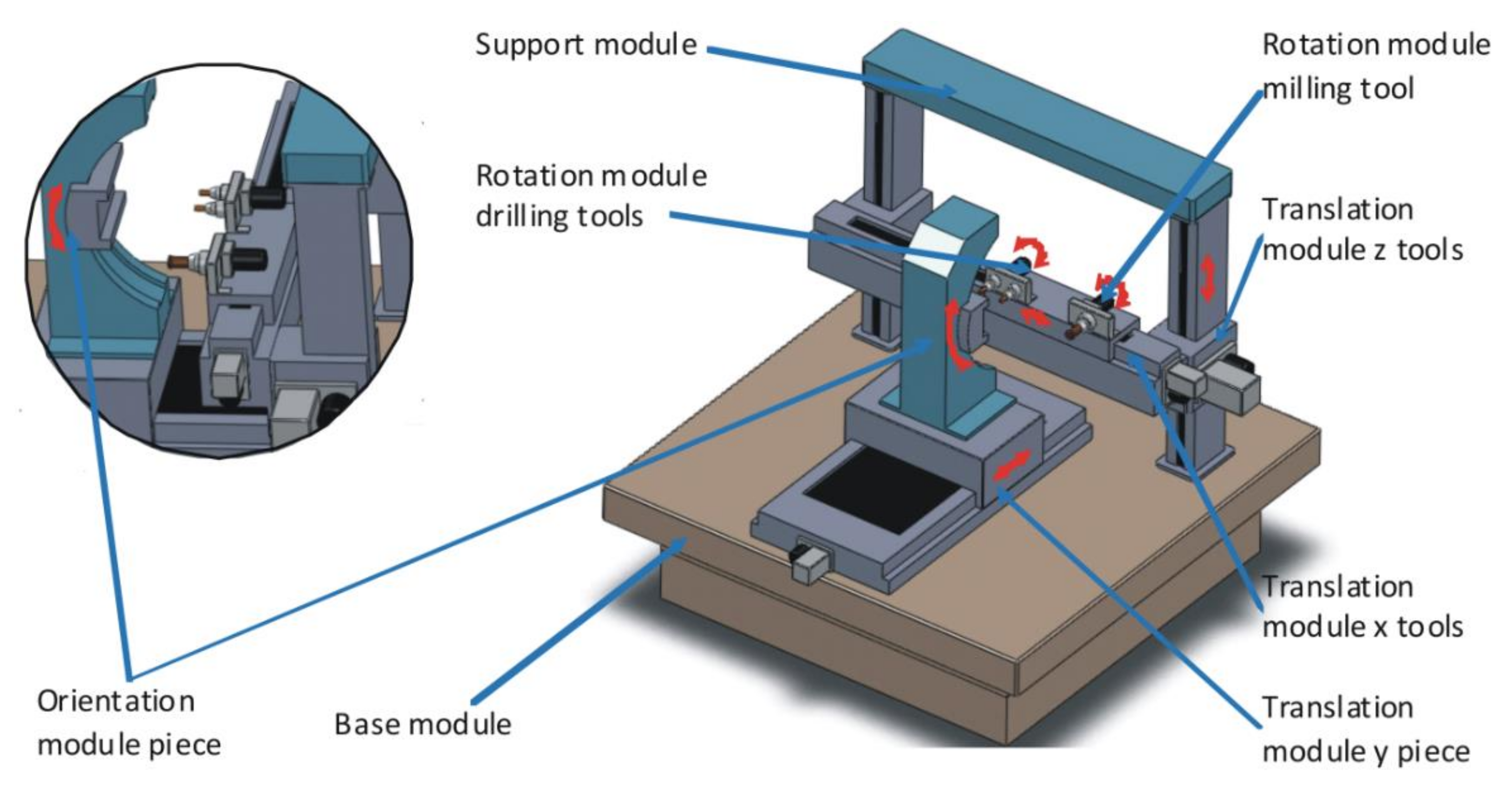

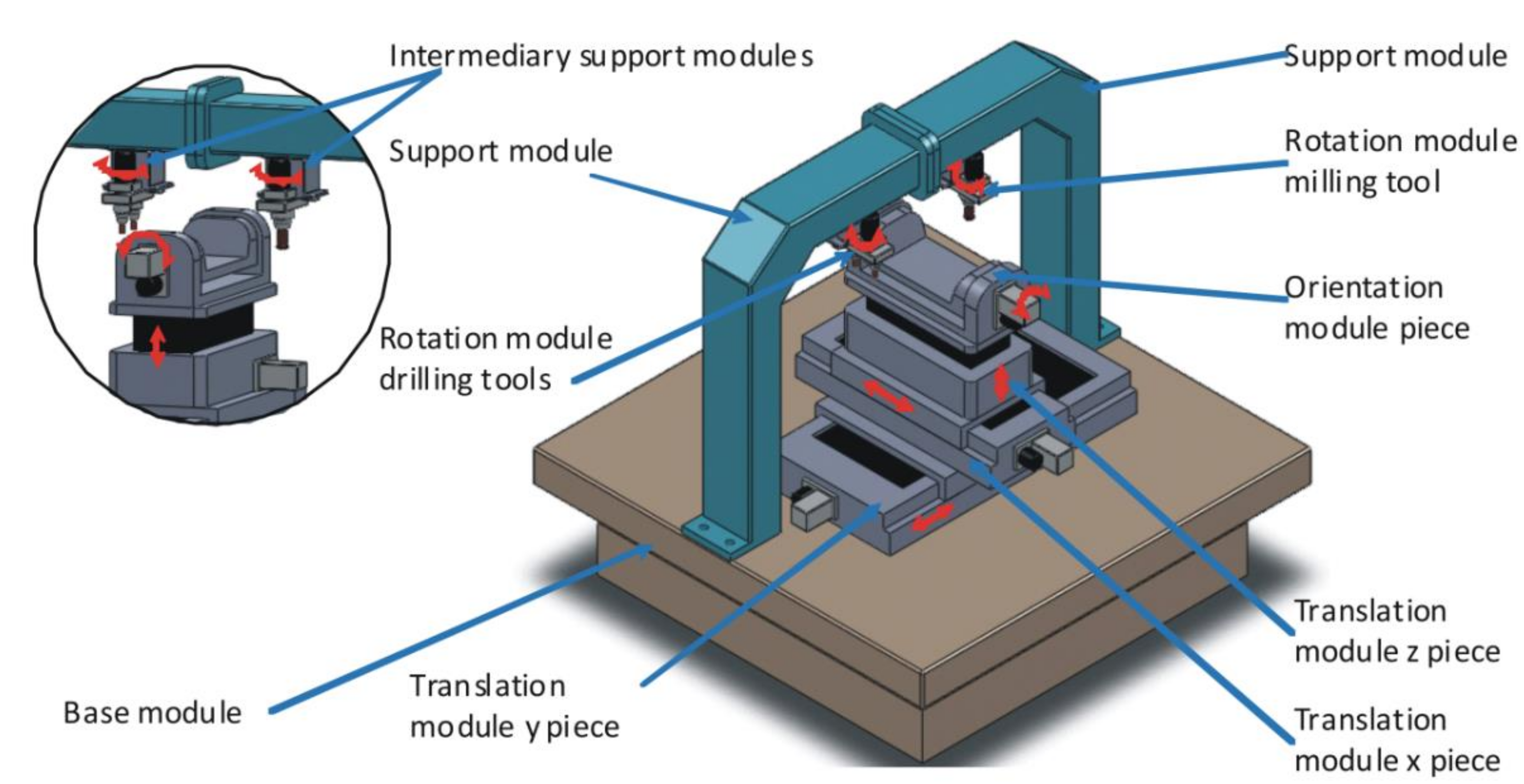

Applied Sciences Free Full Text Algorithm For Designing Reconfigurable Equipment To Enable Industry 4 0 And Circular Economy Driven Manufacturing Systems Html

Machining Of Shape Memory Alloys Springerlink

Impact Of Powder Additives In Liquid And Gaseous Dielectric Fluids On Electrical Discharge Machining Through Aerospace Region Applications A Review Sciencedirect

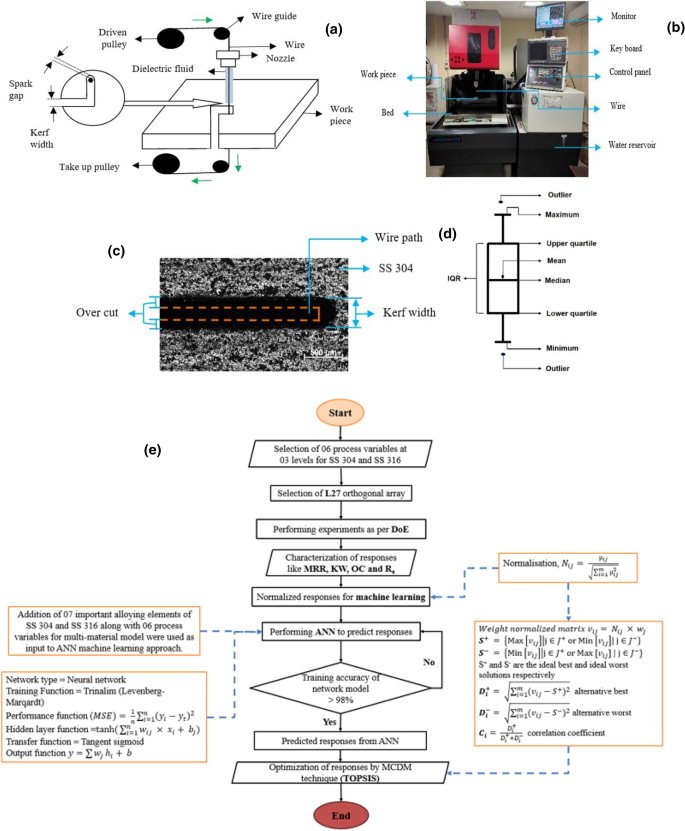

Design Of Multi Material Model For Wire Electro Discharge Machining Of Ss304 And Ss316 Using Machine Learning And Mcdm Techniques Springerlink

Recent Advances In Micro And Nano Machining Technologies

Electrical Discharge Machining Definition Working Parts Applications Advantages Disadvantages With Pdf Learn Mechanical

Applied Sciences Free Full Text Algorithm For Designing Reconfigurable Equipment To Enable Industry 4 0 And Circular Economy Driven Manufacturing Systems Html

Electrical Discharge Machining Definition Working Parts Applications Advantages Disadvantages With Pdf Learn Mechanical

Applied Sciences Free Full Text Algorithm For Designing Reconfigurable Equipment To Enable Industry 4 0 And Circular Economy Driven Manufacturing Systems Html

Spark Erosion Machining An Overview Sciencedirect Topics

Modern Cnc Machine Working Amazing Cnc Machining Machines

Applied Sciences Free Full Text Algorithm For Designing Reconfigurable Equipment To Enable Industry 4 0 And Circular Economy Driven Manufacturing Systems Html